PRODUCT

Buffing Machines

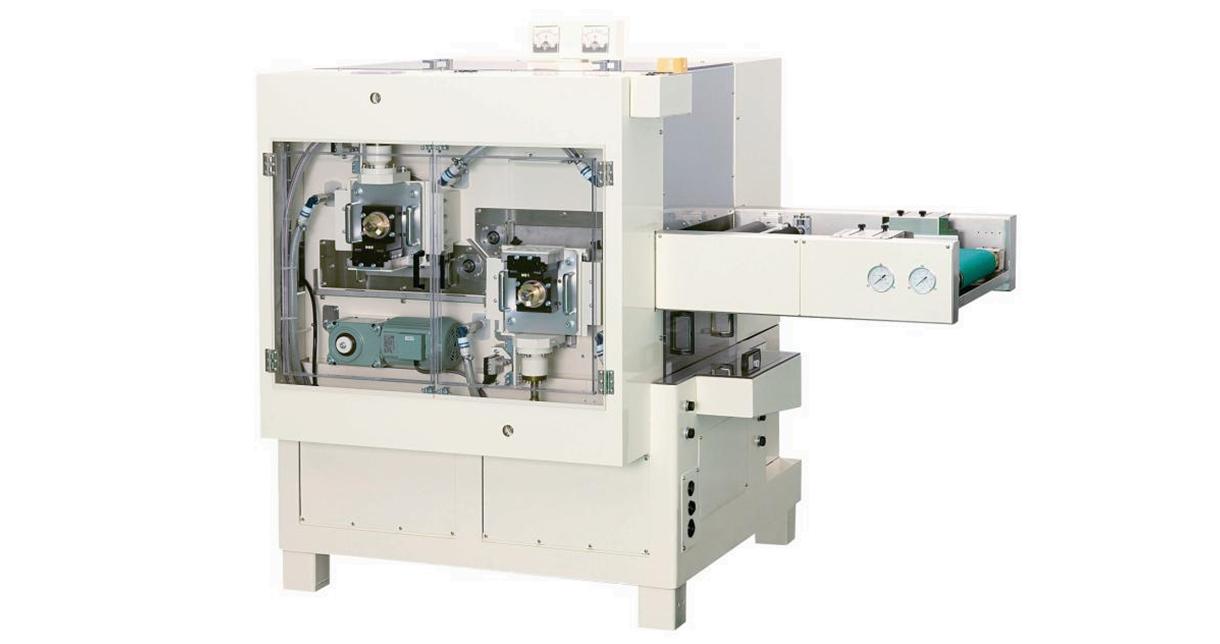

Clutch Plate Deburring MachinesICD-300

MACHINERY

These machines make treatment possible on small-size work surfaces, through the use of magnets in the back-up section. While the machines use a conveyor belt transport structure, they can process both sides of the work material in one go. As well as automobile parts, they can also be applied to a diverse range of other materials requiring deburring.

| Work Size | φ100 - φ290 mm |

| Board Thickness | 0.3 - 8.5 mm |

| Effective Processing Width | 290mm |

Applications/Features

- * Post-press deburring treatment that is able to remove even large burrs.

- * Deburring and finishing processes are conducted simultaneously, adjusting surface roughness to meet desired standards.

- * By processing both sides of the material simultaneously, the resultant grain and surface roughness is kept consistent across both sides.

- * Materials are passed through the machine on a conveyor using magnetic attraction, making the machines compatible with any work material size.

- * The max. conveying speed is over 10m/min, resulting in high productivity, and good quality during continuous production.

- * The type of deburring wheel can be chosen from a number of options, including ceramic, non-woven fabric, and brush type wheels.

- * The deburring wheel has a long operating life, contributing to reduced costs when compared to other deburring methods.