Our Business

01 DEVICE

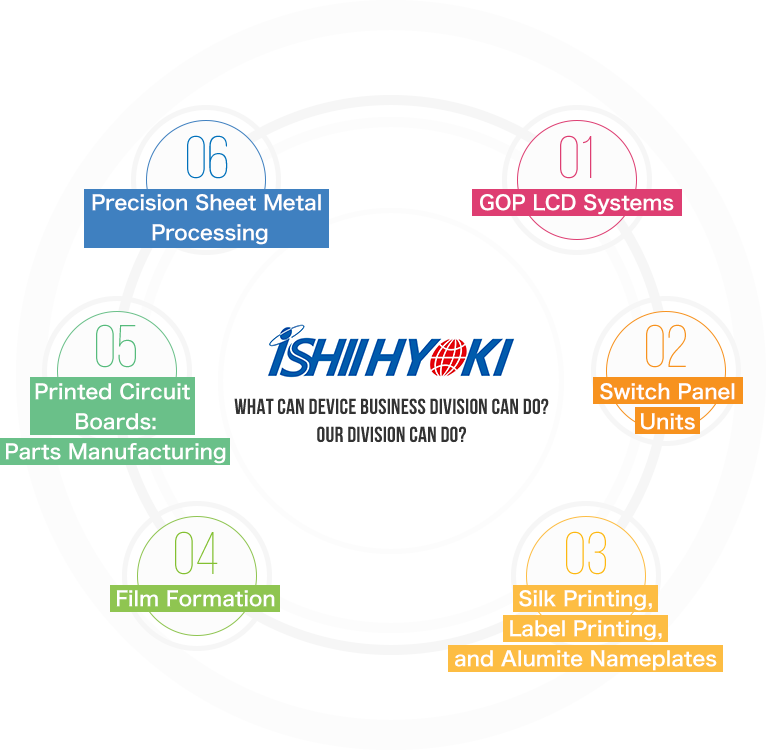

We make full use of the latest cutting-edge technology to manufacture electrical machinery and peripheral electronic machinery parts.

Our devices division has expanded our business operations from its origins in the brass plate etching products manufactured by the current chief executive Mr. Mineo Ishii, to a diverse range of fields, including nameplates, printed circuit boards, membrane switches and other forms of system control, maintaining a focus on technology. The main characteristic of our division is the total manufacturing solutions that we offer - we conduct all aspects of the production process in-house, from initial designs and drafts to material procurement, sample production, implementation, assembly and product inspection. We are also an open-minded and versatile organization, with a swift working pace and a passion for cutting-edge technology, and provide our clients with flexible and highly detailed solutions and technological expertise to meet their requirements.

Providing the best solutions to suit your needs.

-

- 01

- GOP LCD Systems

The Graphic Operation Panel (GOP) 5000 series is a range of next-generation display panels with powerful expressive capabilities. The panels are housed in compact casing, and with a myriad of display options available, they provide an intuitive HMI for a diverse range of automated office equipment, measuring equipment, medical equipment, and food preparation equipment.

The lineup also includes high-end options with a range of additional functions, including video input, audio output, and ethernet capabilities.

The panels may also be installed with BURU touch systems, and provide stable, consistent control in all operating environments. -

- 02

- Switch Panel Units

These reliable units do not break down or malfunction in even the toughest of conditions. Our switch panels are highly reputed in the manufacturing equipment industry, where reliability is prized above all else. As well as our original ISI membrane and Excel switch panels themselves, we are also able to support our clients in all of their switch panel requirements from cases to control boards, using our technological expertise to develop and produce our own custom products in-house. Using our many years of experience, we can provide your business with total solutions for your manufacturing needs.

-

- 03

- Silk Printing, Label Printing, and Alumite Nameplates

"Our facilities include cleanrooms with high quality production capabilities, and our printing equipment is able to respond to a diverse range of specifications and quantity requirements, from small to larger order sizes. In order to offer detailed solutions to customer requirements, we are able to provide a range of material options including polyester, acrylic, metal and paper. We also offer versatile printing options including multicolor, 3D and hairline printing, allowing for freedom in design and layout in product manufacturing.

In addition, we are also able to provide added value through a diverse range of cosmetic treatments, including embossing, potting, mold printing, crêpe patterns and silver/gold leaf pressing." -

- 04

- Film Formation

At Ishii Hyoki, we are able to provide a diverse range of printing expressions and functions based upon our silk printing technology, including leather grain and matte printing, realistic faux wood halftone printing, and metallic printing with a bright sheen. In addition, we are also able to manufacture products with a three-dimensional appearance by administering film formation to the base material and applying insert molding to resin.

The products provide new potential in a diverse range of fields including industrial machinery, automobile parts, and amusement-related products, for use as control sheets, decorative sheets, and other applications.

-

- 05

- Printed Circuit Boards: Parts Manufacturing

We provide all-in-one in-house solutions, from artwork design to print template production and actual assembly. While we have long been able to offer both single- and double-sided printing, we can also provide flexible and multi-layer circuit board options, using our automated in-house implementation line to deliver manufacturing solutions that include the assembly stage of production. Our expert team also conduct product inspections, taking all possible measures in terms of quality inspection and management to ensure consistently high product quality.

-

- 06

- Precision Sheet Metal Processing

From single sheet to box processing, we offer in-house design and processing solutions that are particularly ideal for sample and small- to mid-scale manufacturing.

In addition, we are also highly skilled in customized products and meeting requirements under tight deadlines, as we conduct all aspects of the manufacturing process in-house.

Our all-in-one production lines are able to respond to highly detailed user requirements and requests.

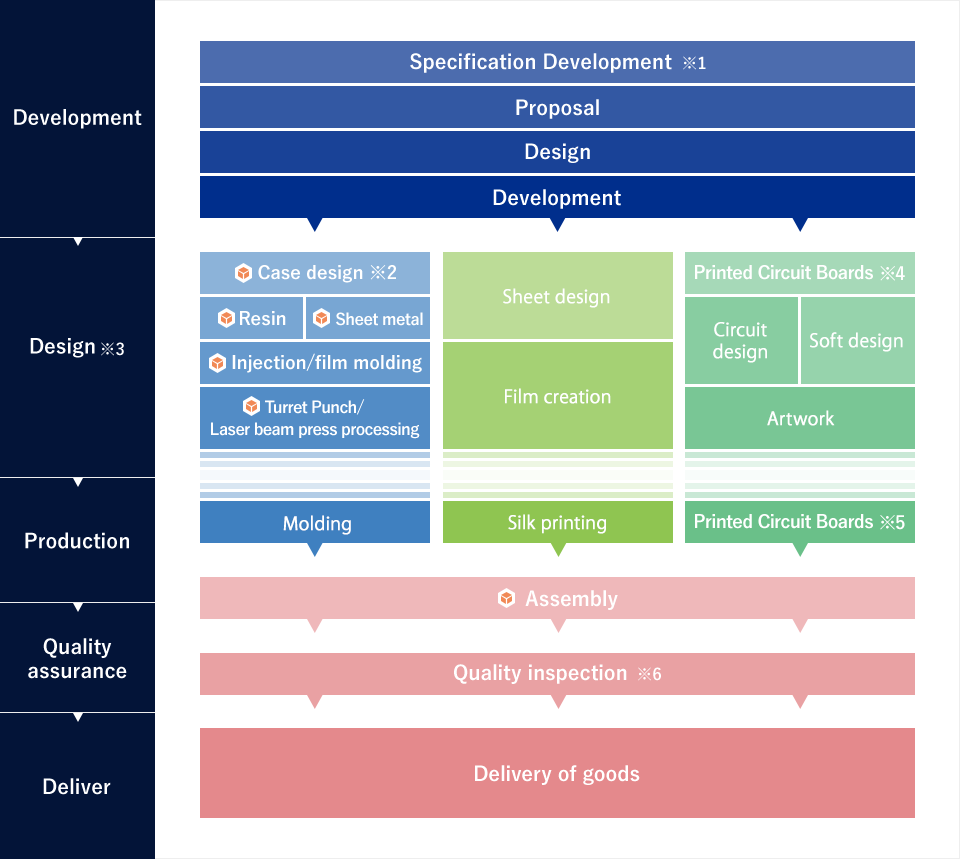

We support our customers throughout the production process using our total development system.

Offering total all-in-one in-house support from the development/proposal stage to design, production, and quality inspections, we provide a wide range of solutions for diverse requirements.

- *1. Following examination of the specification, our engineers propose ideal solutions for client requirements based upon a backbone of rich industry experience and cutting-edge technology.

- *2. We use the latest 3D CAD software in the structural and casing design process. As well as a visual representation of the final product, we are also able to provide simulations of how well the product fits with the case, along with its stress characteristics.

- *3. We select the most ideal formation methods for the casing of each product, taking into consideration manufacturing precision, lot quantity, and the product objective. Whatever the method required, our company has the necessary processing equipment in place at our manufacturing plant.

- *4. We manufacture all components required for silk printing and printed circuit boards in-house, including films and print templates. We also provide flexible responses to custom requirements.

- *5. Our manufacturing plant is equipped with a high-speed implementation line for printed circuit board manufacturing.

Our capabilities include the latest in circuit board technology, including multi-layer, fine-pitch and flexible circuit boards. As we have developed an all-in-one production line covering automated implementation, assembly and the final stages of production, we are able to produce high quality and highly reliable products within in a short timeframe. - *6. Our products are shipped out after undergoing strict quality guarantee inspections, including operational inspections carried out on all units of each product.

We utilize 3D CAD software in our design management line.

We utilize 3D CAD software in our design management line.

Locations

Domestic Locations

- Head Office

-

Kannabe Industrial Park, 5 Asahioka, Kannabe-cho, Fukuyama, Hiroshima Prefecture 720-2113

TEL: 084-960-1200

FAX: 084-960-1202

- Nagoya Office

-

60 Fukiage, Minamiobuchi, Ichinomiya, Aichi Prefecture 491-0014

TEL: 0586-77-8002

FAX: 0586-75-1090

- Shiga Office

-

MAEDA Daiichi Building 1F, 1-4-12 Nishishibukawa, Kusatsu, Shiga Prefecture 525-0025

TEL: 077-561-2975

FAX: 077-561-2979

International Locations

- JPN, INC.

-

LOT9, BLOCK13, CAVITEEPZ, ROSARIOCAVITE4106PHILIPPINES

TEL:63-46-437-1714

FAX:63-46-437-1713

URL:http://www.jpn-in.com